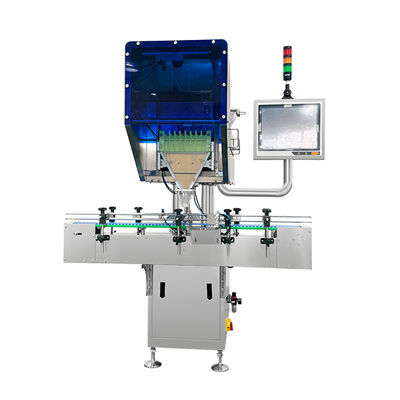

Visual counting machine integrates the advanced image processing technology and automation control technology, mainly used for accurate counting of granular materials.

This equipment is widely used in the pharmaceutical, food, and chemical industries to ensure accurate formulation and packaging of products.

Introduction

The vision counting machine is an automatic equipment that utilizes a high-precision camera to capture images and identify and count granular materials through image processing algorithms. It can efficiently and accurately count particles, and is suitable for various shapes and sizes of granular materials, such as tablets, capsules, seeds, candies, and so on.

Working Principle

(1) Material conveying: Granular materials are uniformly fed into the counting area via a vibrator bowl or a conveyor belt.

(2) Image capture: A high-resolution camera captures the material when passing through the counting area in real time.

(3) Image processing: analyze the number of particles in the image through advanced image processing algorithms.

(4) Counting and output: accurately count according to the number of particles calculated by the algorithm, and transmit the result to the control system or directly display on the operation interface.

Major Constitutes

-Material supply system: includes vibrator bowl, conveyor belt, etc., used for uniformly dispersing materials.

-Image collection system: consists of a high-resolution camera and lighting system for obtaining clear images of the material.

-Image processing system: adopts special image processing software or an embedded system to realize rapid analysis and counting of images.

-Control system: usually equipped with a touch screen for setting parameters, displaying counting results, and controlling equipment operation.

-Output system: Transmit counting results to downstream equipment or keep records.

-Intelligent detection, alarm, and removal system: foreign matter detection and alarm, lack of material detection and alarm, and packaging machine abnormal alarm. The machine has a perfect online detection and removal device.

Technical Parameters

-Counting range: be able to cover from several granules to more than ten thousand, depending on the model of the equipment.

-Counting accuracy: up to ±1% generally, or even higher.

-Processing speed: processes from several granules to more than ten thousand, depending on material characteristics and equipment configuration.

-Applicable materials: applicable to various shapes and sizes of granular materials, such as round, oval, irregular shapes, etc.

-requirements for power supply: usually 220V/50Hz or adjusted according to regional standards.

-Dimensions and weights: vary according to specific models and configurations.

Application

-Pharmaceutical industry: for counting and packaging of tablets, capsules, etc.

-Food industry: suitable for counting candy, chocolate beans, and other foods.

-Chemical industry: It can be used for precise proportioning of chemical reagent particles.

-Agricultural sector: seed counting and packaging.

Features & Advantages

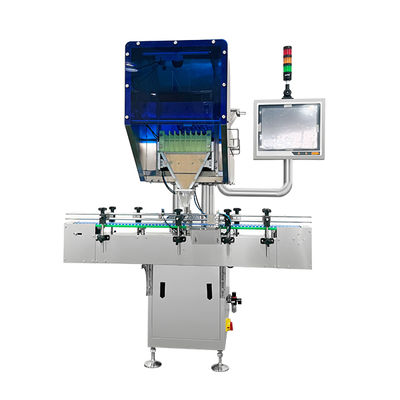

(1) High accuracy: reach sub-millimeter counting accuracy by utilizing image processing technology.

(2) High efficiency: high degree of automation, greatly improving production efficiency.

(3) Versatility: applicable for counting a wide range of materials with strong adaptability.

(4) Visualized operation: touch screen interface is intelligent and easy to operate and maintain.

(5) Data record: data from each count can be recorded for traceability and quality control.

(6) Being dismantled: the corrugated plate/hopper is removable for quick and easy viewing, replacement, and cleaning.

Operation and Maintenance

-Operation training: Operators should be trained to ensure correct operation before new equipment is put into use.

-Periodic inspections: cameras, lighting systems, and mechanical components are regularly inspected to ensure proper functioning.

-Cleaning and maintenance: clean and lubricate the equipment according to the recommendations of the equipment instruction manual so that the equipment is in good condition.

-Troubleshooting: Refer to the equipment manual for initial diagnosis when encountering problems, and contact the manufacturer for technical support if necessary.

Case Presentation

-Pharmaceutical company: by providing a pharmaceutical company with a vision counting machine, help it realize accurate counting and packaging of tablets, and improve production efficiency and product quality.

-Food processing: A customized vision counting machine for a candy manufacturer meets their needs for high precision counting and fast packaging.

Conclusion

Vision counting machine has become one of the indispensable and important equipment in modern production lines with its high precision, high efficiency, and multi-functionality. Vision counting machine will continue to provide more accurate and efficient counting solutions for various industries through continuous innovation and technological advancements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!