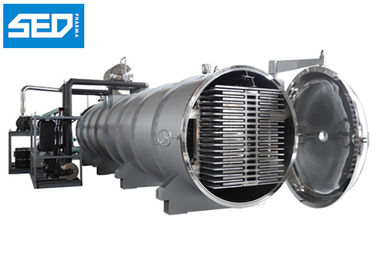

| SED-100DG Freeze Drying Machine |

| |

Product structure |

Technical parameters |

Remarks |

| Design Standard:CGMP |

| ※ Public distribution |

| |

Power (three-phase and five-wire system) |

415V/50HZ |

|

| |

Power |

127Kw/300A |

|

| |

heating function |

81kw |

Can choose steam heating |

| |

Cooling water qty |

≥56m3/h(T≤30℃/P=0.1-0.15Mpa) |

|

| |

Cooling water of refrigerant system |

43 m3/h |

|

| |

Cooling water by heat |

10 m3/h |

|

| |

Cooling water of vacuum pump |

2 m3/h |

|

| |

Compressed air |

≥0.45 m3/min(P=0.5-0.8Mpa) |

|

| |

Defrost water |

≥8T (Temperature 50-60℃,pressure 0.1MPa) |

|

| |

Whole volume |

12000*2520*3500 |

(According to design standard) |

| |

Structure |

Integral (Horizontal drum-type) |

|

| |

Total weight |

14000kg(About) |

|

| ※ Chamber |

| |

Performance parameters |

| |

|

Design and manufacturing standards |

Vacuum vessel standard |

| |

|

Design pressure of chamber |

-0.1Mpa |

| |

|

Design temperature of chamber |

120℃ |

| |

Main components |

| |

Material |

SUS304/δ8mm |

|

| |

Shape |

Horizontal drum-type |

|

| |

Lock method |

Handle tighten type |

2 pieces |

| |

Direction of opening door |

According to the design |

user select |

| |

Door materials |

SUS304 |

|

| |

External decoration of chamber |

Painting |

Painting color determined by the user |

| |

The roughness of chamber and door |

Ra≤0.6μm |

|

| |

Observation window on the door |

set two observation windows on each side of the central door /φ200mm |

2 pieces |

| |

Observation window on the chamber |

Φ200mm / set two observation windows with a 12V light at the side of chamber |

2 pieces |

| |

Door sealing |

Sealed with silicone rubber O-section |

1 pair |

| |

Trolley guide at top of Chamber |

SUS304 |

1 piece |

| |

Material temperature sensor at left and right |

Import thermocouple (Origin: U.S. Omega / A-level precision) |

3+3 pieces |

| |

Technical Features |

| |

1 |

Stainless steel is polished with excellent brand to ensure surface roughness to ensure sterility requirements |

| |

2 |

There has not any parts at the bottom of chamber to facilitate cleaning and maintenance |

| |

3 |

Cabinet, board level, and hose are tested after multiple procedures to ensure without leakage |

| ※ Shelf |

| |

Performance parameters |

| |

|

Total usable area of shelves |

110.16M2 |

| |

|

Maximum temperature of lamellar |

+100℃ |

| |

|

Shelf heating rate (no load) |

≥3℃/min |

| |

|

Shelf cooling rate(no load) |

≥3℃/min |

| |

Main components |

| |

Lamellar material |

Aluminum alloy D31 (6363) |

|

| |

Design pressure |

0.5MPa |

|

| |

Surface Treatment |

anode oxidation process, (thickness 6μ) + Shading |

|

| |

number of board layers |

Symmetrical hanging (17 +17 blocks) |

|

| |

Shelf spacing |

77mm |

|

| |

Shelf dimensions |

540mm*6000mm*18/block |

|

| |

Heating main tube |

SUS304 |

4 pieces |

| |

Connecting hose |

SUS304 |

68 pieces |

| |

Shelf temperature probe |

Import thermocouple (Origin: U.S. Omega / A-level precision) |

1+1 piece |

| |

Technical Features |

| |

1 |

Shelf has high strength and can withstand long-term use; |

| |

2 |

Shelf through a dedicated machining can guarantee high demand flatness; |

| |

3 |

Shelf heating temperature can be controlled at ± 0.3 ℃ (PID regulator) |

| ※ Condenser |

| |

Performance parameters |

| |

|

Design Standard |

Vacuum vessel standard |

| |

|

Cabinet design pressure |

-0.1Mpa |

| |

|

Maximum condensate ice |

2000KG/batch/set |

| |

Main components |

| |

Condenser material |

SUS304/δ8mm |

|

| |

Condenser shape |

Horizontal drum-type |

|

| |

Observation window at the rear of the storage body |

set two observation windows on each side of the central door /φ200mm |

2 pieces |

| |

Observation window of the storage body |

Φ200mm / set an observation window with a 12V light at the side of |

1 piece |

| |

external |

painting |

User select |

| |

The inner surface roughness |

Ra≤0.6μm |

|

| |

Defrosting Mode |

Water mist spray |

|

| |

Defrost nozzle |

SUS304 |

9 pieces |

| |

Defrost water |

8T/(50-60℃,0.10Mpa) |

|

| |

Coil pipe material |

SUS304 |

|

| |

Coil form |

Snake-type coil |

|

| |

Inner pipe material |

R404a |

|

| |

Tightness test value |

1.2Mpa/30min, packing 24hr without any leakage. |

|

| |

Pressure test |

1.8Mpa/30min, no significant deformation |

|

| |

Temperature probe |

Import thermocouple (Origin: U.S. Omega / A-level precision) |

1 piece |

| |

Technical Features |

| |

1 |

Stainless steel is polished with excellent brand to ensure surface roughness to ensure sterility requirements |

| |

2 |

Argon welding, forming an internal and external, to ensure pipes cleanly and without leak |

| |

3 |

The inside wall of the cold trap is cleaned by special way to ensure no dirt, ensure the system clean |

| ※ Refrigeration System |

| |

Performance parameters |

| |

|

Condenser cooling rate (no load) |

30℃→-40℃≤30min |

| |

|

lowest temperature (no load) |

≤-55℃±5℃ |

| |

Main components |

| |

compressor model |

German BITZER /HSN8571 -125 |

1 set |

| |

Refrigerant |

R404a |

|

| |

Power |

92Kw |

|

| |

Oil separator |

HANGZHOU SAFETY EQUIPMENT CO.,LTD |

1 piece |

| |

Oil cooler |

HANGZHOU SAFETY EQUIPMENT CO.,LTD |

1 piece |

| |

Oil filter (filter core changeable |

Germany Bitzer 25um |

1 piece |

| |

Oil flow switch |

Germany Bitzer |

1 piece |

| |

Plate type exchanger economizer |

Sweden (SWEP) or (Alfa) |

1 piece |

| |

High / low pressure protection device |

The Danish DANFOSS |

3 pieces |

| |

Chilled mirror |

DANFOSS |

1 piece |

| |

High / low pressure gauge |

Switzerland REFCO oil immersed type shockproof pressure gauge |

3 pieces |

| |

Refrigerant filter (detachable) |

Shell: Taiwan / core: USA EMERSON |

1 set |

| |

Expansion valve (condenser) |

Users provide their own |

1 piece |

| |

Expansion valve (cold) |

The Danish DANFOSS TES |

1 piece |

| |

Solenoid valve (condenser leakage) |

The Danish DANFOSS |

1 piece |

| |

Solenoid valve (cold) |

The Danish DANFOSS |

1 piece |

| |

Solenoid valve (oil) |

The Danish DANFOSS |

1 piece |

| |

Hydraulic protection controller |

The Danish DANFOSS/KP1-1101 |

1 piece |

| |

Water cooled condenser |

HANGZHOU SAFETY EQUIPMENT CO.,LTD |

1 piece |

| |

Safety valve |

3060/33C |

1 piece |

| |

Pipe insulation |

USA ARMAFLEX |

Closed foam flame retardant |

| |

Technical Features |

| |

1 |

Screw compressor is used Blitzer refrigeration compressor, more stable performance, reliable, easy to maintain |

| |

2 |

Temperature and pressure of compressor has multiple protection features |

| |

3 |

Suction filter settings, prevent degeneration of stolen goods and acid materials into the compressor chamber , corrosion internal parts and refrigeration oil. |

| |

4 |

Exhaust temperature protection set to avoid oil degeneration in extreme conditions , to reduce the exhaust temperature by cooling motor |

| |

5 |

Compliance with the Montreal Convention, with environmentally friendly refrigerants; |

| ※ Vacuum system |

| |

Performance parameters |

| |

|

Extraction rate |

105 Pa→133 Pa≤20min |

| |

|

Ultimate vacuum |

≤13.3Pa |

| |

|

Vacuum adjustable range |

13.3-200Pa |

| |

Main components |

| |

vacuum pump type / number |

JAPAN ULVAC VSN7501 |

1 sets |

| |

The number of roots pump models |

RTO-600S/Shanghai CuiMan vacuum electrical and mechanical manufacturing co., LTD |

1 set |

| |

Vacuum sensor |

Chengdu ZhengHua electronic instrument co., LTD (A-level precision) |

1 piece |

| |

Vacuum guide plate |

SUS304/Baffle / baffle height 1600mm |

1 pair |

| |

Power Units |

22+5.5=27.5Kw |

|

| |

Cooling water |

0.18 +1.8=2m3/h |

|

| |

Vacuum Explorer main valve |

Taiwan ALISUN/DN150/ Electrical Activity of stainless steel valves |

1 piece |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!